What is the cost of making a boundary wall?

How much does a precast concrete panel cost?

Building a boundary wall is a critical investment for property security and aesthetic enhancement in India. With the rise of modern construction techniques, precast boundary walls have gained popularity due to their durability, speed of installation, and cost-effectiveness. This article explores the costs involved in constructing a precast boundary wall in India, focusing on key factors like precast boundary wall making machine, manufacturing processes, and regional pricing trends.

1. Cost Factors for Precast Boundary Walls

The total cost of a precast boundary wall depends on several variables:

Material Quality: Cement, aggregates, and steel reinforcement (e.g., high-tensile prestressed wires) form the core materials. Grades like M25 to M40 concrete influence strength and pricing.

Wall Height and Thickness: Standard walls range from 6–8 feet in height, with thicknesses between 100–200 mm. Industrial walls often require thicker panels (200–300 mm) for load-bearing purposes.

Design Complexity: Decorative patterns, barbed wire provisions, or custom elevations increase costs. For example, M30/M35-grade walls with security features cost 10–15% more than basic designs.

Labor and Installation: Skilled labor charges vary by region. In Delhi-NCR, installation costs range from ₹50–₹100 per square foot.

2. Role of Precast Boundary Wall Making Machines

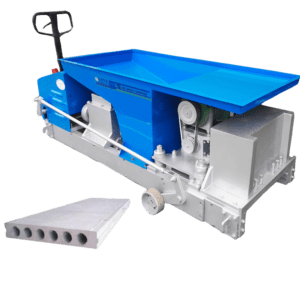

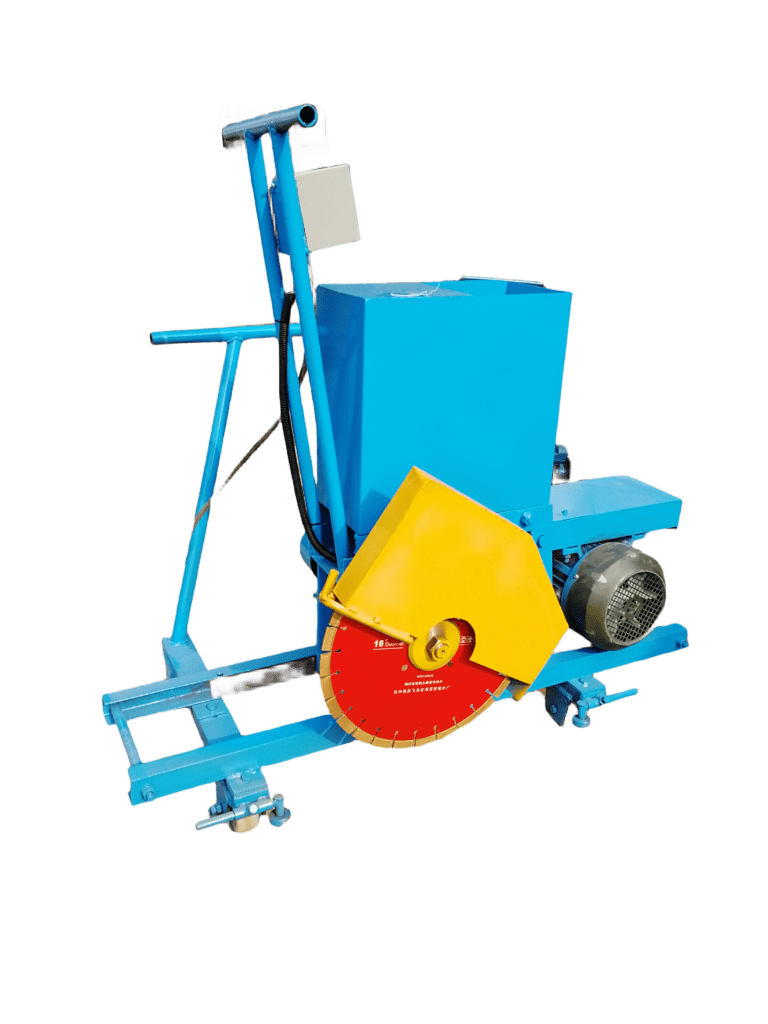

The use of precast boundary wall making machines in India has streamlined production, reducing labor dependency and ensuring uniformity. Key machinery includes:

Concrete Block Machines: Models like the JQT 4-15 or JQT 6-15 (priced at ₹15–₹30 lakh) automate molding and curing, producing up to 4,000 blocks per day.

Extrusion Machines: For industrial-scale production, companies like HENAN KELAI INDUSTRIAL CO.,LTD offer specialized machines (₹20–₹50 lakh) that integrate steel strand tensioning and vibration compression for high-density panels.

Lightweight Wall Panel Lines: Advanced systems from manufacturers like KELAI MACHINE Equipment enable the production of soundproof, fire-resistant panels at ₹80–₹120 per square foot.

Investing in machinery significantly lowers long-term costs, with ROI achievable within 2–3 years for medium-scale projects.

3. Precast Boundary Wall Manufacturing Process

The precast boundary wall manufacturing process involves five key stages:

Material Preparation:

Cement, sand, aggregates, and water are mixed in precise ratios. High-strength M40-grade concrete is preferred for industrial walls.

Steel reinforcement (prestressed wires) is cut and shaped for structural integrity.

Mold Design and Casting:

Custom molds (wooden or steel) are used to shape panels. Automated machines like the JQT series ensure consistent dimensions and surface finish.

Concrete is poured into molds and vibrated to eliminate air pockets.

Curing:

Panels are cured in controlled environments (7–14 days) to achieve optimal strength. Steam curing accelerates the process for large orders.

Transportation:

Finished panels are transported via road using specialized trucks. Logistics costs average ₹5–₹10 per kilometer in North India.

On-Site Installation:

Panels are erected using cranes or manual labor, anchored to pre-dug foundations. Installation takes 2–3 days for a 100-meter wall.

4. Regional Cost Breakdown

- Delhi-NCR: ₹120–₹180 per square foot (including materials and labor).

- Punjab/Haryana: ₹100–₹150 per square foot due to lower labor costs.

- South India: ₹150–₹220 per square foot (higher material transport expenses)

5. Why Choose Precast Over Traditional Walls?

Speed: Precast walls reduce construction time by 60% compared to brick-and-mortar methods.

Sustainability: Reusable molds and optimized material usage minimize waste.

Conclusion

The cost to build a precast boundary wall in India ranges from ₹100 to ₹220 per square foot, depending on design, machinery, and location. By leveraging precast boundary wall making machines in India and standardized manufacturing processes, property owners can achieve durable, cost-efficient solutions tailored to residential, commercial, or industrial needs. For large-scale projects, partnering with certified manufacturers like HENAN KELAI INDUSTRIAL CO.,LTD ensures quality and compliance with industry standards.