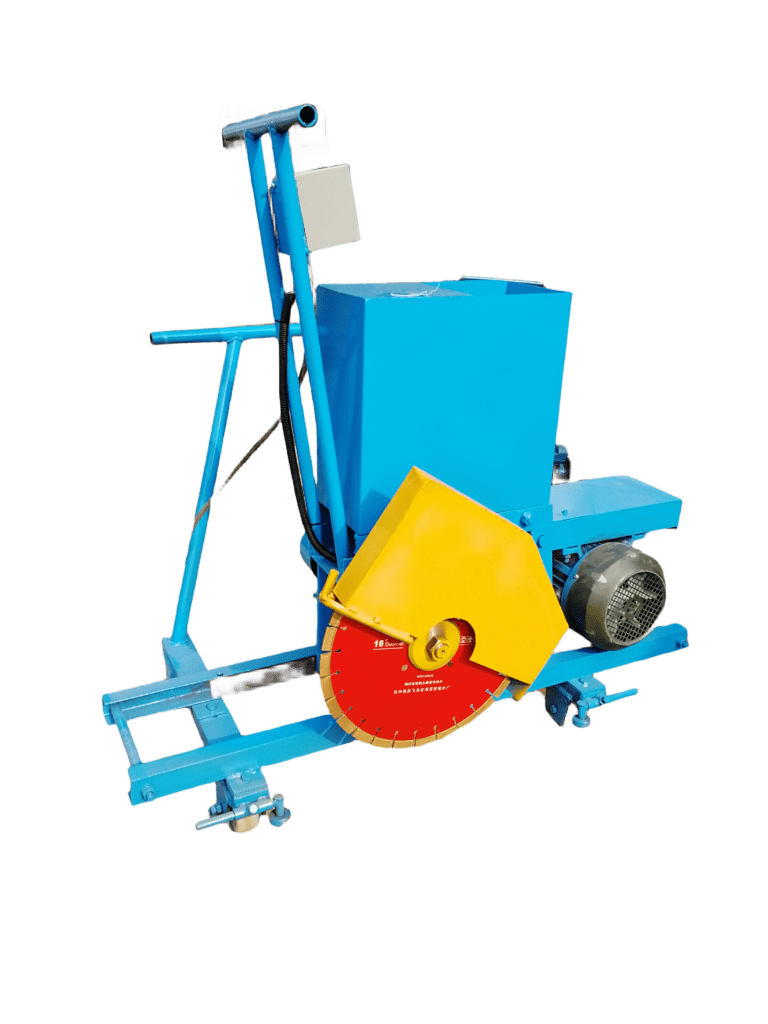

Precast concrete floor machine is a kind of mechanical equipment specially used for producing precast concrete floor.

Working principle:

The pre-mixed concrete material is injected into the mold and formed by vibration or pressure. After the concrete hardens, a prefabricated floor slab with precise dimensions and stable structure can be obtained. This process is highly automated, and everything from batching, mixing, conveying, forming to curing can be completed independently by concrete floor slab machine.

Key Features:

Efficient production: Compared with the traditional method of pouring floor slabs on site, precast concrete floor slab machines can achieve batch production, greatly improving production efficiency. For example, in a factory environment, a large number of precast floor slabs can be produced in one day to meet the needs of multiple construction projects.

Reliable quality: Machine production can ensure the dimensional accuracy and quality stability of the floor slabs. The uniform vibration and stable pressure during the production process make the structure of the precast floor slabs dense, high in strength, and not prone to quality problems such as cracks and deformation.

Material saving: Through reasonable design and precise control, the precast concrete floor slab machine can reduce the use of materials such as concrete and reduce construction costs while ensuring the strength of the floor slab.

Easy operation: After continuous technological improvements, the operation of the floor slab machine is becoming easier and easier. Only a small number of operators need to be trained to operate it, which reduces the requirements for manual skills.

Strong applicability: Precast floor slabs of various sizes, shapes and specifications can be produced according to different architectural design requirements to meet diverse construction needs.

Technical parameters: Different models of precast concrete floor slab machines have different technical parameters, mainly including board height, board width, number of holes and diameter, board making speed, main motor power, vibrator model, etc. For example, a common model has a plate height of 12 cm, a plate width of 50 cm, a plate making speed ≥ 1.1 m/min, and a main motor power of 4 kW.

Application areas:

Residential buildings: In residential construction, concrete floor slab machine/precast slabs can be used to build floor slabs and provide stable structural support. At the same time, its hollow design can also play a certain role in sound insulation and heat insulation, improving the living comfort of the residence.

Commercial buildings: In commercial buildings such as shopping malls, hotels, and office buildings, precast slabs can be used for large-area floor slab laying, speeding up construction progress and shortening the construction period.

Industrial buildings: Industrial plants, warehouses, etc. have high requirements for the bearing capacity and span of slabs. Precast concrete floor machines can produce large precast slabs that meet these requirements, which is convenient for construction and installation.

Maintenance:

Regularly check the various components of the equipment, such as vibrators, reducers, motors, etc., to ensure their normal operation, and promptly discover and deal with potential faults.

The vulnerable parts of the equipment, such as molds, bearings, etc., should be replaced and maintained regularly to ensure the production efficiency and product quality of the equipment.

Keep the equipment clean, and clean the concrete residues and dust on the surface of the equipment in time to avoid corrosion and damage to the equipment.