What are the wearing parts of precast concrete floor machine?

The vulnerable parts of precast concrete floor machines mainly include the following categories:

Mold part

Inner membrane core tube: In the production process of precast concrete floor machine, the inner membrane core tube plays the role of forming the hollow structure inside the floor. Since the concrete will produce continuous extrusion and friction on the inner membrane core tube during the injection and vibration molding process, and will also bear certain stress during demolding, after repeated use, the inner membrane core tube is prone to deformation, wear and even damage, affecting the molding quality of the hollow structure of the floor, so it is a consumable part.

Outer mold: The outer mold is in direct contact with the concrete and bears the pressure and impact of the concrete. In long-term use, the sand and stone particles in the concrete will continuously wear the surface of the outer mold, and frequent opening and closing operations may also cause deformation and cracks in the outer mold, reducing its dimensional accuracy and sealing performance, thereby affecting the appearance and size specifications of the precast floor. It is one of the consumable parts that need to be replaced or repaired regularly.

Vibration system components

Vibration motor: The vibration motor is a key component that is set up to ensure that the concrete injected into the mold can be evenly and densely distributed. It runs continuously at high speed during operation. The bearings inside the motor are subjected to large centrifugal force and friction for a long time, which is prone to wear, resulting in abnormal motor vibration, increased noise, and even failure to produce vibration effects normally, affecting the molding quality of prefabricated floor slabs. Its service life is relatively limited, and it is a component that often needs maintenance and replacement.

Vibrator connection parts: The vibration motor is connected to the main structure of the equipment or the mold through some connection parts (such as couplings, connecting bolts, etc.). These connection parts will be subject to alternating stress during the vibration process, and are prone to loosening, breaking, etc. Once a problem occurs, the vibration transmission effect will deteriorate, so it is also a part that is more easily damaged.

Transmission parts

Belt: If the precast concrete floor machine adopts belt drive, the belt will gradually wear and age due to friction with the pulley and repeated stretching and bending during the long-term power transmission process, which will be manifested as peeling, cracks or even breakage on the surface, which will affect the stability of power transmission and cause problems such as uneven equipment running speed. It needs to be replaced in time.

Chain and sprocket: Some equipment uses chains and sprockets for transmission. During the operation of the chain, the links are constantly rubbed against each other. The teeth of the sprocket will also wear during the meshing process with the chain. The chain may be elongated and relaxed. The wear of the sprocket teeth will affect the accuracy and stability of the transmission. Both are vulnerable transmission elements.

Gear: Gear transmission is also common in floor machines. During frequent meshing operation, the tooth surface will be worn. In the long run, the tooth shape will change and the tooth thickness will become thinner, which will affect the correct meshing and power transmission efficiency between gears. It is easy to cause faults such as tooth hitting and increased transmission noise. It is a vulnerable part that needs attention and timely replacement.

Other components

Seals: There are many parts in the equipment that need to be sealed, such as the sealing strips of the mold, various sealing gaskets in the hydraulic system (if any), etc. The sealing strips are easily worn and aged during frequent opening and closing of the mold and contact with concrete, and lose their sealing function, leading to problems such as leakage; the sealing gaskets may be deformed and damaged due to long-term pressure, temperature changes and other factors, causing hydraulic oil leakage or other medium leakage, affecting the normal operation of the equipment, so they also belong to the category of consumable parts.

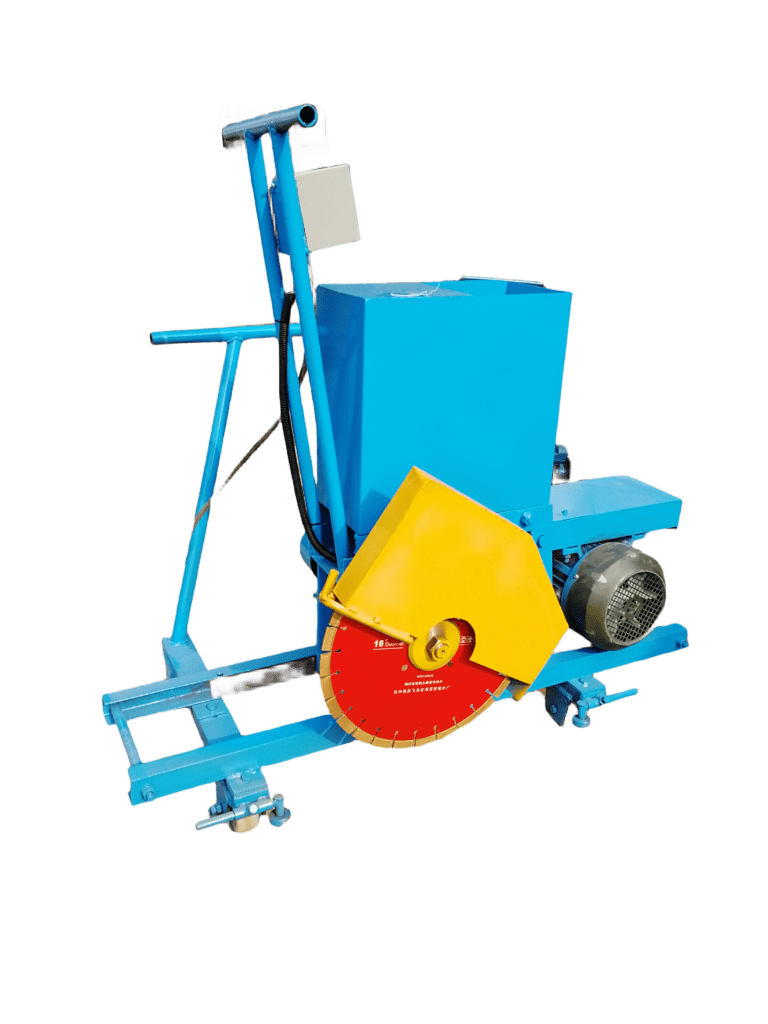

Cutting tools (if there is a cutting process): Some precast concrete floor machines have a cutting function, which is used to cut the formed prefabricated floor according to the required size. When the cutting tool cuts hard concrete materials, the cutting edge will continue to wear and become blunt, affecting the efficiency and quality of cutting, and it is necessary to sharpen or replace the new tool regularly.