Opening a concrete precast panel factory requires specific machinery designed for producing various types of concrete panels, including walls, floors, and other structural elements. Here are the main types of machines you’d typically need:

1. Batching Plant

Purpose: Mixes concrete ingredients (cement, water, aggregates, and additives) to produce consistent batches of concrete.

Requirements: Should have high precision in weighing and mixing to ensure quality and consistency. A plant with automated systems can improve efficiency.

Key Features: Consider a plant with integrated controls, easy maintenance, and the capacity to handle the volume of production you intend.

2. Concrete Casting Beds (Stationary or Tilting Tables)

Purpose: These are the flat surfaces or molds where concrete is poured and shaped into panels.

Types:

Stationary casting beds are fixed, often in a horizontal position.

Tilting tables allow easy demolding by tilting, which reduces strain on both the panel and workers.

Key Features: Reinforcement anchors, embedded electric, and plumbing channels can be pre-fitted in these molds.

3. Molding Machines and Molds

Purpose: To shape the concrete into the required dimensions and designs.

Types: Modular molds that allow flexibility in panel thickness, surface texture, and dimensions.

Key Features: Durable materials and adjustability for different panel designs and sizes.

4. Concrete Spreader and Vibrator

Purpose: Distributes concrete evenly across the mold and removes air pockets, ensuring even compaction and a smooth surface.

Key Features: Variable speed and vibration control to handle different concrete types and panel thicknesses.

5. Reinforcement Placement Machine (Optional)

Purpose: Automates the placement of rebar, mesh, and other reinforcements into the molds.

Key Features: Works well for large operations where uniform reinforcement is essential for structural integrity.

6. Curing Systems (Steam Curing or Drying Chambers)

Purpose: Accelerates the curing process, allowing the concrete to harden uniformly and quickly.

Types:

Steam curing systems use controlled heat and humidity.

Drying chambers maintain a controlled environment without steam.

Key Features: Automated control over temperature and humidity settings to ensure quality.

7. Demolding Crane or Robot

Purpose: Removes the cured panels from the molds and moves them to storage.

Key Features: Automated systems increase safety and reduce damage to panels.

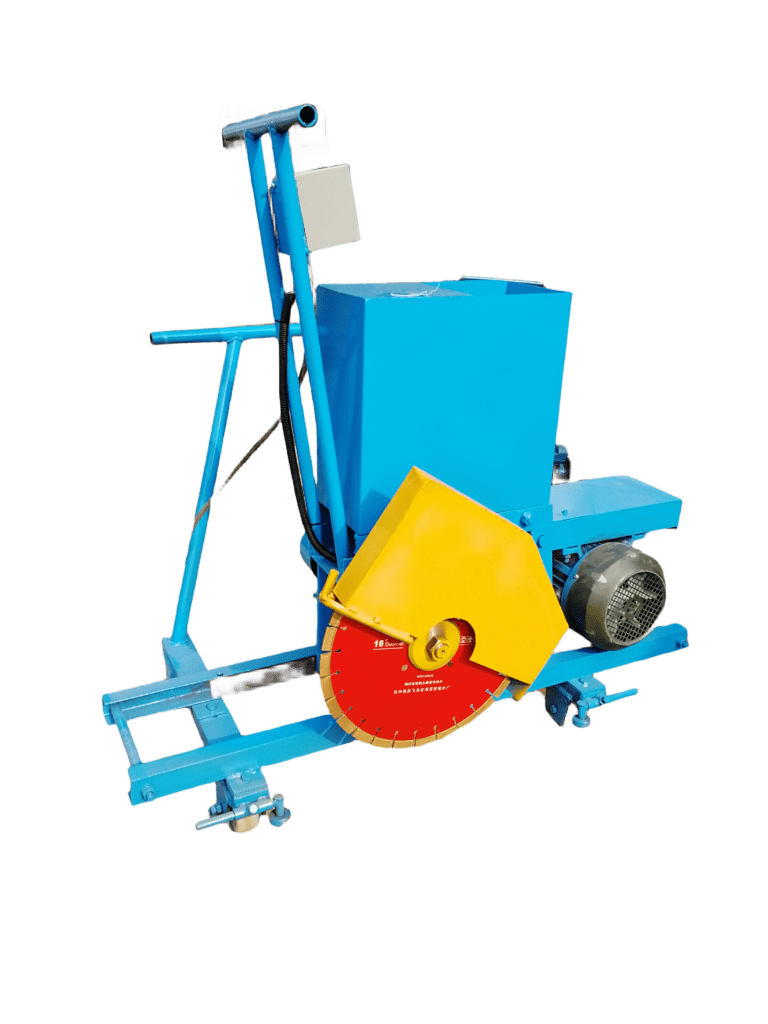

8. Finishing Machines

Purpose: Applies the final touches to panels, including polishing, texturing, and adding surface treatments.

Types: Can vary based on the desired finish (smooth, textured, or architectural).

Key Features: Flexibility to apply multiple types of finishes depending on customer requirements.

9. Storage and Transport Equipment

Purpose: Stores finished panels and transports them within the factory or for delivery.

Types: Racks, lifting cranes, and forklifts.

Key Features: Ensure that storage systems are organized to handle different panel sizes and avoid overcrowding, which can damage finished panels.

10. Quality Control and Testing Equipment

Purpose: Ensures each panel meets required specifications for strength, size, and finish.

Types: Compression testing machines, dimensional gauges, and surface finish testers.

Key Features: Consider equipment that integrates with software for recording quality metrics.

Optional Machinery for Automation and Efficiency

For larger operations, automated solutions can be highly beneficial:

Automated Mixing and Batching Systems: Increase accuracy and reduce labor requirements.

Automated Palletizing and Packaging Systems: For end-of-line processing to bundle and prepare panels for shipping.

Having a clear production line layout and determining the output capacity are also crucial in deciding the exact type and scale of each machine.

Commonly used precast concrete panel machine types:

Prestressed slab forming machine

Purpose: Produce prestressed concrete slabs, such as hollow slabs, solid slabs, etc. Suitable for floor slabs, wall panels, roof panels and other products.

Type: Slipformers and extrusion machines are often used to make prestressed concrete slabs. Slipformers are suitable for longer production lines, while extruders can produce continuously more efficiently.

Features: Fast molding speed and high production efficiency, especially suitable for mass production needs.

Concrete distributor and vibrator

Purpose: Distribute concrete evenly into the mold, and use vibration to eliminate bubbles and improve the density of the board.

Features: Adjustable speed and vibration intensity to ensure surface quality and thickness consistency of different boards.