CONCRETE WALL PANEL CUTTING MACHINE

About the wall panel cutting machine

Main structure and working principle

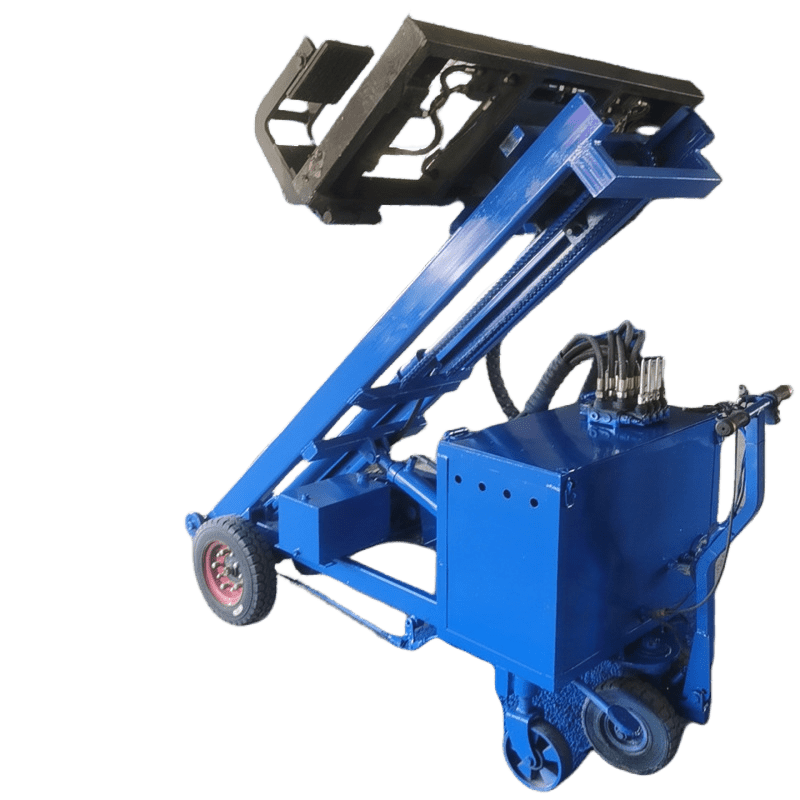

Structural composition

Cutting blade: This is the core component, usually made of high-strength alloy steel. The thickness, diameter and number of teeth of the blade will vary according to the cutting object. For example, when cutting thick reinforced concrete slabs, thicker blades with larger diameters and more teeth are required to ensure the efficiency and quality of cutting./ wall panel cutting machine.

1.Working Principle

When the power device is started, the cutting blade is driven to rotate at high speed through the transmission system. When the rotating blade contacts the surface of the floor, it uses the sharp edge of the blade and the cutting force generated by the high-speed rotation to gradually cut the floor material. During the cutting process, the operator controls the cutting path of the cutting machine through the walking mechanism to complete the cutting operation of the floor according to the predetermined size and shape.

2. Application scenarios

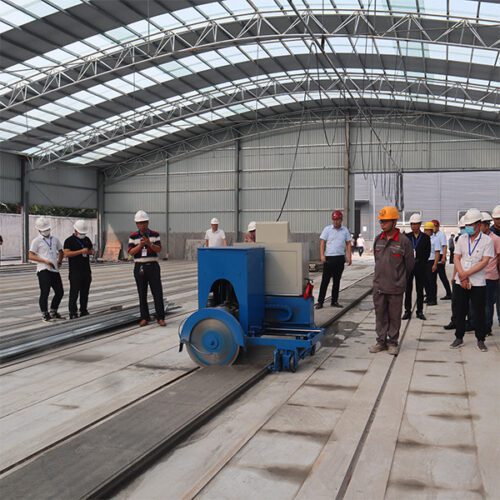

Precast panel cutting and segmentation

In the production of precast panels, concrete wall panels, and concrete floor panels, a concrete cutting machine is used to cut and segment the panels.

Building demolition project

During the demolition of old buildings, part of the floor structure needs to be removed. The floor cutting machine can accurately cut out the floor area that needs to be demolished to avoid unnecessary damage to the surrounding structure. For example, in the renovation project of old buildings in the city center, for some situations where the building facade needs to be retained and the internal floor is demolished, the floor cutting machine can efficiently complete the cutting task while ensuring safety.

Renovation and expansion in building construction

When a building needs to be functionally transformed or expanded, it may be necessary to open a hole in the original floor for the installation of facilities such as stairs, elevators, or ventilation ducts. The floor cutting machine can accurately cut out holes that meet the size requirements, and the edges after cutting are neat, which is conducive to subsequent construction. For example, in the renovation project of a shopping mall, in order to install a new escalator, a floor cutting machine can be used to cut a suitable opening on the floor.

3. Operation precautions

3. Operation precautions

Cutting process operation

During the cutting process, keep the cutting speed uniform and avoid being too fast or too slow. Too fast a cutting speed may cause the blade to wear more and the cutting surface to be uneven; too slow a cutting speed may affect work efficiency. And pay attention to the cutting situation. If you find that the blade is shaking abnormally or the cutting resistance is too large, you should stop cutting immediately, check the cause and deal with it.

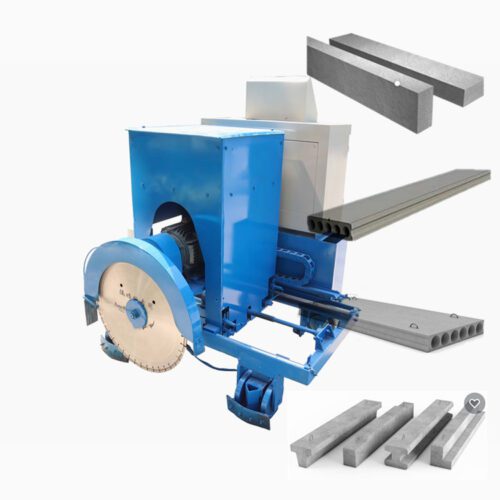

Main Models of wall panel cutting machine

1. HC400: cutting thickness ≦120mm; cutting width 0-1200mm; diameter of cutting blade 400mm

2. HC500: cutting thickness ≦180mm; cutting width 0-600mm; diameter of cutting blade 500 mm

3. HC600: cutting thickness ≦200mm; cutting width 0-600mm; diameter of cutting blade 600mm

4. HC700: cutting thickness ≦260mm; cutting width 0-600mm; diameter of cutting blade 700mm

5. HC800: cutting thickness ≦330mm; cutting width 0-600mm; diameter of cutting blade 800mm. etc.

concrete cutting machine

Other Supporting machines for making concrete Wall Panel Machine