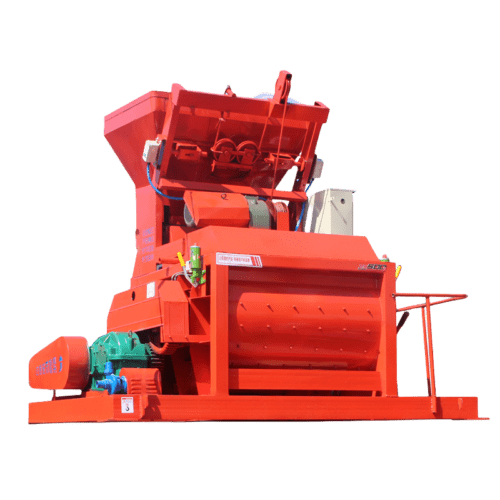

Concrete Mixer

Overview of Concrete Mixer

JS series is a type of forced concrete mixer with double-horizontal-shaft. The machine is with many advantages such as reasonable design structure, strong mixing effect, good mixing quality, high efficiency, low energy consumption, novel layout, high degree of automation, and convenient use and maintenance. The mixer can supply good concrete for the precast concrete industry.

Here we focus on introducing JS500, a common concrete mixing model.

The JS500 concrete mixer can produce 0.5CBM concrete materials per mixing cycle. So it is also called 0.5 cubic concrete mixers. The productivity of the mixer is 25m3 per hour which is mostly used as the host machine of the HZS25 mixing plant. The mixer machine can also be combined with the PLD batching machine to form a simple concrete mixing station. Of course, the machine also can work alone without any other supporting machines to mix the concrete.

The main structure of JS500

1 Mixing system

The mixing blade is made of high-alloy wear-resistant materials, mixing uniformly and stably.

2. Discharge system

Three control modes: hydraulic control, pneumatic control, manual control;

3.Water supply system

The throttle valve can adjust the flow of water,

The total water supply is adjusted by the time relay

4.Electrical System

It has the functions of short circuit protection and overload protection.

5.Deceleration system

1. Drum concrete mixer Structural composition

Drum

This is the core part of the mixer, generally a cylindrical metal drum. The size (diameter and length) of the drum will vary depending on the model and production capacity of the mixer. The inner wall of the drum is usually equipped with special mixing blades, which are spiral, arc-shaped and other shapes. The spiral blades can push the material in one direction when the drum rotates, so as to achieve full mixing of the material and also help unloading.

Drive device

Mainly includes a motor or engine, and transmission parts. Motor drive is suitable for places with stable power supply, such as mixing plants on large construction sites. Engine drive is convenient for use in remote construction sites without electricity. Transmission parts usually include belts, gears, etc., which are used to transmit power to the drum so that the drum rotates at a suitable speed.

Flat mixer

Concrete Mixer

Feeding device

The position and size of the feed port are reasonably designed to facilitate the feeding of raw materials such as cement, sand and gravel into the drum. The feed port usually has a funnel-shaped structure, which makes it easier for materials to enter the drum.

Discharging device

The discharge port is located at one end of the drum. When the concrete mixing is completed, the concrete can be discharged by opening the discharge port. There are many ways to unload, the most common ones are inclined unloading and reverse unloading.

Concrete Mixer Use

Drum concrete mixer is a kind of equipment commonly used in construction projects, used to mix cement, sand, gravel, water and other materials into concrete.

How it works

When the drive device is started, the drum begins to rotate. As the drum rotates, the cement, sand, gravel, water and other materials in the drum are constantly turned and mixed under the action of the mixing blades. The materials are pushed from one end of the drum to the other end by the blades, and then brought back to the starting end, and the cycle repeats. In this process, the materials are fully in contact with each other, the cement is evenly wrapped on the surface of the sand and gravel particles, and the water is evenly distributed in the entire material system, eventually forming a uniform concrete. For example, during the mixing process, the dry cement and sand and gravel initially put in are in a separated state. After a few minutes of rotation and mixing, they will become a concrete slurry with a certain fluidity.

Different Types of Concrete Mixers

Supporting machines for concrete batching plant

With the accurate electronic weighing system, the PLD series concrete aggregate machine is used for working with loaders or belt conveyors, cement silos, and various types of mixers to form a fully automatic or semi-automatic batching station, ensuring the mixing ratios of sand, gravel, and other aggregate accuracy and stability. The main models of the PLD series concrete batching machine include PLD800, PL/1200, PL/1600, PL/2400, PL/3200, PL/4800, etc. The systems can automatically weigh 2-4 kinds of aggregate materials

- Cement silos are generally used to storing bulk cement in concrete mixing batching plants. Cement silo is a kind of closed tanks for storing bulk materials, suitable for storing various bulk materials such as grain, cement, and fly ash. The silo is equipped with a material-level system. , It can display the location and amount of the material, and the hole device can relieve the solidity caused by the material deposition fo long-time. The silo is equipped with an Arch breaking device and a dust removal system.

LSY series cement concrete screw auger conveyor is the main unit for mechanical transport operation of industry and agriculture, which uses a motor to drive screw rotation and move material to achieve conveying purpose. LSY series cement concrete screw auger conveyor is suitable for all industries such as building material, chemical industry, power industry, metallurgy, coal industry and grain industry, for horizontal or tilted transportation for powdery, granular and small lump materials, such as coal, dust, residue, cement and grain which their temperature is less than 200℃.

The raw material warehouse is used for storing bulk cement and sand, and it is part of the concrete mixing station. The entire concrete mixing station can sufficient materials for the prefabricated concrete plant.

If you want to build a precast concrete panel production plant, we can provide a full set of production equipment to help you achieve it.

Other Supporting machines for making concrete Wall Panel Machine