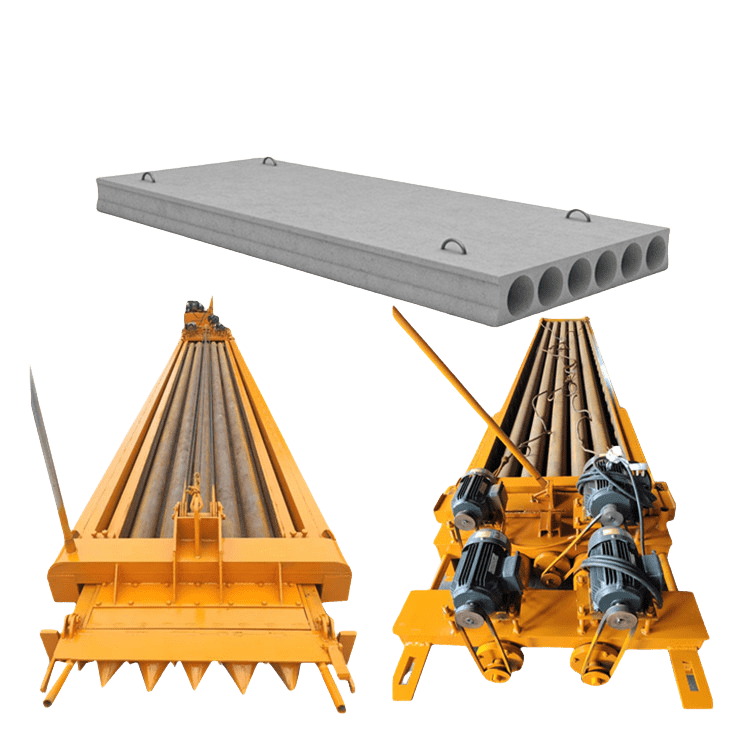

Concrete hollow core slab molding machine

Working principle of floor machine:Inner vibration and pulling mould

The concrete hollow core slab molding machine is developed and improved on the basis of traditional manual and ground anchor pull die mold equipment. The whole hollow core slab machine is composed of a driving system(winch)and a hollow core slab mold frame. The inner slab mold is equipped with a 6-7 pieces vibration tubes with vibatring cores that connect the vibrating motors. After pouring concrete into the mold, the motor drives the vibrating cores shaft to rotate at high speed and generate a strong and uniform internal eccentric vibration force. After the hollow core slabs formed, the winch will pull the mold out. And then, it starts the next production.

Main Technology details

- Slab thickness: 120-300mm

- Slab width:600,900,1200mm

- Slab length or span: 6000-7500mm

Benefits and Advantages:

- Low cost.

- Traditional technology; Simple structure, easy to operate

- Reliable quality and easy to maintain

- −Concrete slab mold forming machine is a special equipment used to produce various concrete slabs, commonly used in construction projects and the production of precast concrete components. Its main function is to evenly distribute the concrete in the mold through mechanical vibration, extrusion or other molding processes, and quickly solidify and shape it. The following are its basic working principles and main features:

Floor slab machine advantages

1. Working Principle

Concrete slab mold forming machines generally include feeding, vibration, molding and demoulding:

Feeding: Concrete mixture is fed into the mold cavity through a conveyor belt or other means.

Vibration molding: Concrete material is compacted and molded through high-frequency vibration, pressing or other means.

Demolding: The solidified concrete slab is pushed out of the mold by the demoulding system.etc.

2. Main features

High degree of automation: usually equipped with an automated control system, which can achieve accurate metering and molding, and improve production efficiency.

High production efficiency: mechanical vibration and molding process can be quickly finalized, suitable for mass production of concrete slabs.

Stable structure: The equipment has a solid structure and is suitable for the production of concrete slabs of different specifications.

hollow core slab molding machine

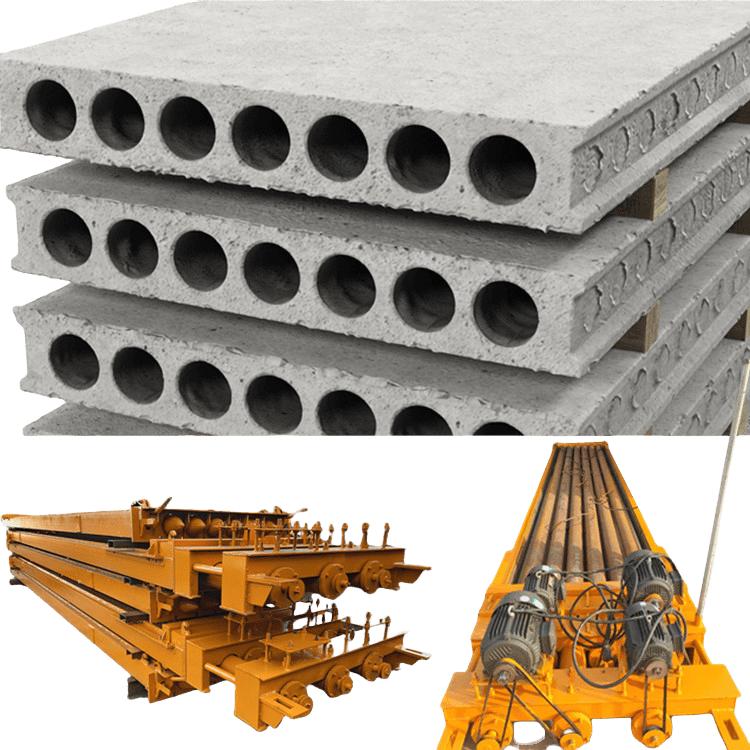

Floor machine production and delivery photos

Other Supporting machines for making concrete hollow core slab